Price of Sterling Silver!!!!!

I have tried to hold my pricing so far this year but the price of sterling silver has risen over 35% since January 1, 2025. With that kind of increase, I feel I must adjust my prices to cover my additional costs. I try to make sure the price of my jewelry reflects the value and craftsmanship of the pieces. If and/or when the price of sterling silver comes down, I will adjust my pricing to reflect it. Keep your fingers crossed that it will come down soon.

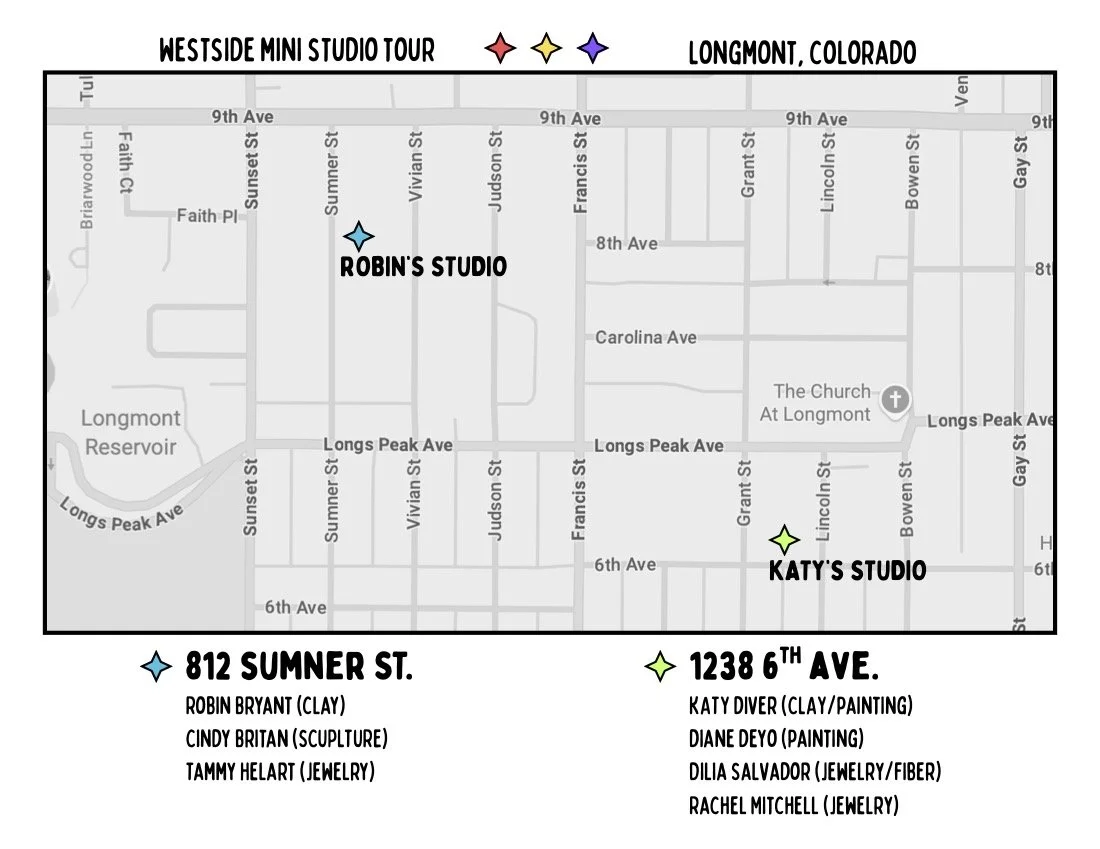

Splendent Stones is in the Westside Mini Studio Tour

I will be showing Splendent Stones Jewelry at Robin Bryant’s studio at 812 Sumner St. in Longmont, Colorado. We are here Friday, September 5th 4PM-7PM with Happy Hour delights and Saturday, September 6th 10AM-4PM. Take a stroll thru the Westside of Longmont to visit the two studio and see the work of seven local artists. Hope to see you there!

EBCA 2025 Spring Studio Tour

It’s that time of year again! I will be opening my studio during the East Boulder County Artists Association’s 2025 Spring Studio Tour! I am at Studio #24 on the tour map. Also showing here will be - Debra Stanger and Malena Hirschfeld. These ladies are fabulous painters. You will get to see three artists at one location! We have all been busy creating new work to share with you.

We hope you can join us Saturday April 26th and Sunday April 27th, 10:00 am to 5:00 each day.

It’s that time of year again! I will be opening my studio during the East Boulder County Artists Association’s 2025 Spring Studio Tour! I am at Studio #24 on the tour map. Also showing here will be - Debra Stanger and Malena Hirschfeld. These ladies are fabulous painters. You will get to see three artists at one location! We have all been busy creating new work to share with you.

We hope you can join us Saturday April 26th and Sunday April 27th, 10:00 am to 5:00 each day.

Kingman Turquoise March 2021

Just got back from our semi-annual trip to Lake Havasu City, Arizona to see my son, his wife and our two grandsons. Weather was really nice (not too hot there this time of year!). And to top it off, we missed the snowpocalypse in the Front Range of Colorado!

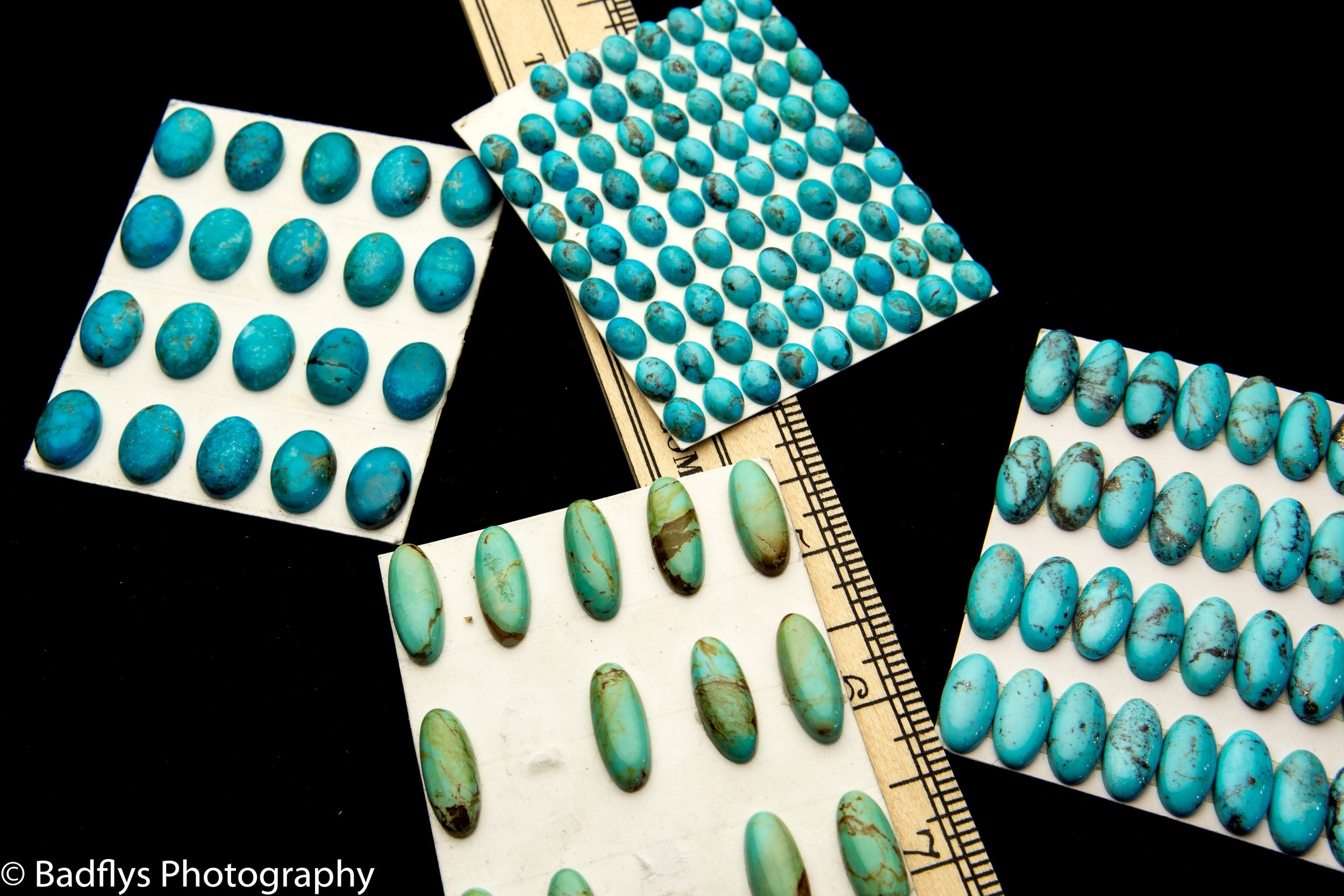

Had to stop in Kingman, Arizona at Colbaugh Processing to look for new Turquoise stones! Got some earring sets for designing earrings. Will be coming soon to the website.

I have had people ask me about the Purple Turquoise I get from Colbaugh. They also have bright green. What Colbaugh does is, take the scraps left over from cutting turquoise beads, dye the turquoise and mix with bronze or copper bits, spiny oyster shell, mix with resin and then pressure pressed to form blocks that lapidarists can then cut cabochons, or beads. This is a great use of turquoise because nothing goes to waste and a “new” stone is created for jewelers to use in their work.

Kingman Turquoise from Colbaugh Processing

Kingman Turquoise from Colbaugh Processing, what makes it special. Custom made jewelry with Kingman Turquoise

Every time I go anywhere I am always on the lookout for good natural stones that I can use to make one of a kind jewelry pieces. On a recent trip to Arizona to visit family I had the chance to meet a new stone cutter and make a visit to Colbaugh Processing to buy some Kingman Turquoise. I’ll share more about the new stone cutter in a later blog. Let’s talk about Kingman Turquoise and Colbaugh Processing and turquoise.

Picking through the turquoise beads to find the right ones

Colbaugh is THE place to buy Kingman Turquoise as well as other stones. Here, a jewelry maker can buy raw turquoise stone, polished turquoise cabochons and turquoise beads of many different shapes and sizes as well as block turquoise.

Colbaugh Processing mines their turquoise from the Mineral Park Mine, in the Cerbat Mountains 14 miles northwest of Kingman. This mining site has been active for over 1000 years. S.A. “Chuck” Colbaugh acquired the rights to mine this area for turquoise in the early 1960's and the family continues to mine for turquoise to this day. All of the processing, cutting and polishing of stones happens at the Colbaugh site 7 miles north of Kingman AZ.

Kingman turquoise is known for it’s deep blue color and it’s black veining or matrix pattern. The blue color of Kingman Turquoise has become the industry standard for turquoise color. The Kingman mines also produce some stunning green turquoise. The Colbaugh family continues to mine and process excellent quality turquoise from multiple locations north of Kingman, AZ.

The American Southwest, including Arizona, New Mexico, Colorado, Nevada are some of the most prolific producers of turquoise. There are well known turquoise mines all over the southwest. Sleeping Beauty, Bisbee, Cripple Creek and High Lonesome to name a few. Production at these mines varies with many grades of turquoise being produced. Pure natural untreated turquoise is extremely fragile and rare. If you are searching for jewelry made with pure, natural turquoise be prepared to pay handsomely, it will be the most expensive turquoise on the market.

Turquoise is naturally a relatively porous and soft stone (5-6 on the Mohs scale). Only a small proportion of the turquoise pulled from any mine is naturally hard enough to be used in jewelry making without damage. The action of cutting polishing and setting would cause the stone to crumble. Softness of turquoise leads to higher porosity. That allows the turquoise to absorb contaminants such as oil and residue from handling. This will change it’s color over time.

To strengthen and seal the turquoise most of the turquoise mined today is stabilized. Stabilization is a process developed back in the 1950s. In the process of stabilization the natural stone is pressure infused with some sort of resin that strengthens and seals the stone. This process is very well proven and common. Stabilized Turquoise is easier to cut, polish and work and more resistant to color change. This stabilization also makes turquoise more affordable. High quality turquoise is stabilized with the minimum amount of clear stabilizer required to strengthen and seal it.

A selection of the Kingman Turquoise that I bought. The smallest are 6mm and the larger green stones are 18mm

A virtual tour of my studio

About a year ago my nephew, Kody Helart, did a video of me and my studio in Longmont Colorado, as part of his final project at the Art institute of Colorado.

It's a good advertisement for my work and will provide some insight to my motivation and my creative vision.

To see a what's available now or to talk about custom designed pieces contact me via email.

For more of Kody' work check out This video it gives you a good sample of his work. He's a talented young man.

Thanks, Kody for the video.